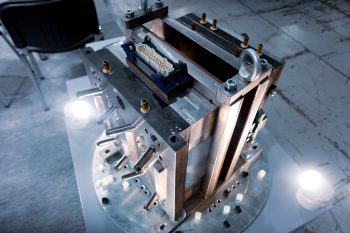

Hexagon’s Manufacturing Intelligence division announced today the release of HxGN Mould & Die, a suite of dedicated CAD/CAM (computer-aided design and manufacturing), engineering, and automation tools empowering mould and die and tool manufacturers to increase efficiency, reduce costs, and produce high quality tools for their customers across industries ranging from automotive to aerospace and beyond. The suite was developed to empower mould designers and makers to achieve operational excellence in the design and manufacturing of plastic injection moulds, progressive dies, forming dies, and similar tools.

Capabilities of the suite include CAD/CAE (computer-aided design and engineering) for plastic injection mould design, CAD/CAE for progressive die design, CAD for manufacturing preparation, CAM for CNC (computer numerical code) machine-tool programming, process simulation and G-code verification and optimisation, shop-floor production intelligence, and automation and collaboration powered by Nexus, Hexagon’s digital-reality platform. The suite’s simulation tools help manufacturers understand the feasibility and cost of mould-making processes with actionable information.

“We took everything we know about mould-and-die manufacturing, including our best-in-class Hexagon technologies, to build a specialised suite that empowers mould and die shops of any size to get the best results faster,” said Chuck Mathews, general manager, production software at Hexagon. “Their competitive edge will be enhanced Nexus, which connects desktop software via the cloud to provide further automation and collaboration opportunities. It also gives teams an easy way to share 3D models with customers through secure web-based visualisation, and consolidate access to libraries for tooling, fixtures, and materials from their desktop apps.”

“The HxGN Mould and Die suite is an exciting development, combining our customers’ challenges with our deep domain knowledge to achieve more. We are refocussing innovation to bring our ecosystem technologies together and help production teams make better informed decisions, faster,” added Parth Joshi, chief product & technology officer at Hexagon.

For plastic-injection mould manufacturers, the suite provides tools for design and engineering, flow simulation, reverse engineering, automated electrode design, and CNC machining. It builds upon Hexagon’s market-leading VISI and WORKNC software, providing comprehensive multi-axis CAM programming capabilities, direct modelling of solids and surfaces, and supports the construction, editing, and repair of complex 3D geometry. Reverse engineering tools allow mould makers to efficiently create solid models from scanned data — a crucial capability for mould repair and redesign, and for creating solid models for manufacturing when CAD files are not available.

The suite also provides plastic flow analysis tools that help shop-floor teams produce cost effective and reliable moulds that will perform as required. These powerful simulation capabilities are simple to use, which ensures that non-engineers or less experienced employees achieve optimal results. The creation of intricate or difficult-to-machine injection mould features is further simplified with the automated design and simulation of EDM (electrical discharge machining) electrodes and their associated holders.

For progressive die manufacturers, HxGN Mould and Die offers a connected workflow with tools for design and engineering, simulation, and production. It enables the step-by-step unfolding of surface and solid models, which gives designers more control over the development of each forming stage. Flexible strip layout capabilities and the ability to simulate the performance of the strip at any stage in the design process make it easy to quickly analyse the results of design changes. The software also helps manufacturers predict springback and offers compensation strategies when challenges with material performance are identified.

The suite supports shops in fully utilising advanced machine tools, using trusted Hexagon VISI and WORKNC software to help programmers optimise machining cycles and specialised cutting strategies specific to mould production. Prior to machining, CNC programs can be simulated and verified using NCSIMUL, the suite’s G-code simulation software, which incorporates the entire machining environment to generate an effective digital twin of the machinery, part, and processes.

For more information, please visit hexagon.com/solutions/mould-die-design-manufacturing, or contact your local Hexagon office.

(0)

(0) (0)

(0)Archive

- October 2024(44)

- September 2024(94)

- August 2024(100)

- July 2024(99)

- June 2024(126)

- May 2024(155)

- April 2024(123)

- March 2024(112)

- February 2024(109)

- January 2024(95)

- December 2023(56)

- November 2023(86)

- October 2023(97)

- September 2023(89)

- August 2023(101)

- July 2023(104)

- June 2023(113)

- May 2023(103)

- April 2023(93)

- March 2023(129)

- February 2023(77)

- January 2023(91)

- December 2022(90)

- November 2022(125)

- October 2022(117)

- September 2022(137)

- August 2022(119)

- July 2022(99)

- June 2022(128)

- May 2022(112)

- April 2022(108)

- March 2022(121)

- February 2022(93)

- January 2022(110)

- December 2021(92)

- November 2021(107)

- October 2021(101)

- September 2021(81)

- August 2021(74)

- July 2021(78)

- June 2021(92)

- May 2021(67)

- April 2021(79)

- March 2021(79)

- February 2021(58)

- January 2021(55)

- December 2020(56)

- November 2020(59)

- October 2020(78)

- September 2020(72)

- August 2020(64)

- July 2020(71)

- June 2020(74)

- May 2020(50)

- April 2020(71)

- March 2020(71)

- February 2020(58)

- January 2020(62)

- December 2019(57)

- November 2019(64)

- October 2019(25)

- September 2019(24)

- August 2019(14)

- July 2019(23)

- June 2019(54)

- May 2019(82)

- April 2019(76)

- March 2019(71)

- February 2019(67)

- January 2019(75)

- December 2018(44)

- November 2018(47)

- October 2018(74)

- September 2018(54)

- August 2018(61)

- July 2018(72)

- June 2018(62)

- May 2018(62)

- April 2018(73)

- March 2018(76)

- February 2018(8)

- January 2018(7)

- December 2017(6)

- November 2017(8)

- October 2017(3)

- September 2017(4)

- August 2017(4)

- July 2017(2)

- June 2017(5)

- May 2017(6)

- April 2017(11)

- March 2017(8)

- February 2017(16)

- January 2017(10)

- December 2016(12)

- November 2016(20)

- October 2016(7)

- September 2016(102)

- August 2016(168)

- July 2016(141)

- June 2016(149)

- May 2016(117)

- April 2016(59)

- March 2016(85)

- February 2016(153)

- December 2015(150)